FRED

BOLARINWA

SHELLING OUT!

Through Harvey Mudd College

Introduction: Our client has been trying to break into the California Black Walnut industry. This unique walnut is known for its complex cell structure as it dissipates force effectively, meaning that cracks do not propagate throughout the shell – making it an extremely tough nut to crack! Our client hopes to establish a profitable small-scale operation that processes the California Black Walnut to harvest its meat. Such an operation could be successful if it were to harvest the meat relatively intact, since the only competitor in the Black Walnut market, a Missouri-based company named Hammons, produces only pulverized nutmeat pieces

Duration: 10 weeks

Tools: Solidworks, Machining: Lathe, Mill, Excel, Google Docs, Figma

Role: Engineer and Product Designer

Task: Our client is looking for a unique way to open black walnuts without damaging the nut meat inside. The design should be able to open at least one nut using a method that is not high impact, leaving the nutmeat in no more than 4 pieces. The method only needs to open the shell, not actually remove the nutmeat; further, at this stage, it does not have to be food-safe.

Background

Our client has been exploring edible plants native to the Southern California region and is particularly interested in the California Black Walnut (J. californica). The nut is naturally drought resistant and has irregularly lobed cells with concave and convex parts that are on average interlocked with 14 neighboring cells”. Of further interest is the chemical juglone, a natural mild toxin produced by all walnut trees yet most concentrated in the Black Walnut. There is active research into the chemical’s detrimental effect on other plants near the walnut tree, but the risk to humans is very low.

Client hopes:

Our client hopes to establish a profitable small-scale operation that processes the California Black Walnut to harvest its meat. Such an operation could be successful if it were to harvest the meat relatively intact, since the only competitor in the Black Walnut market, Hammons, uses a destructive blasting process which fractures both the shell and the nutmeat, leaving only pieces separated out from the shell fragments. She hopes to use the success from our design to increase the awareness of edible native plants and help mitigate food scarcity issues around the country/world.

Let's get analgous with it!

Analogous Research

Due to us only having one client, our user was a little straightforward, so we decided to go right into an interview with the client!

Diggin deeper

UX RESEARCH METHOD 01: INTERVIEWING

Upon discussion with our client over zoom, we have identified a series of functions, constraints, and objectives to implement into our design.

Upon discussion with our client over zoom, we have identified a series of functions, constraints, and objectives to implement into our design.

Our takeaways from our interviews

We should try to avoid high impact methods, such as crushing, that might put the nut meat at stake of being crushed completely

It must come out as intact as possible, or in four intact quarters if need be.

The design needs to be INGENIOUS

Questions we wanted to explore from the interview

-

Is the force located to somewhere specific and whats the surface area in which the force is applied?

-

How might we apply minimally invasive force through the inside of the nut as minimally as possible?

From there, we made a Piecewise Comparison Chart

This was done to gauge the client's pain points are see what characteristics of the design to value the most

-

-We decided having a minimally invasive force was the highest priority since the nut meat needs to be in fourths, a gentle approach is required.

-

-Ensuring the safety of users and maintaining a compact design ranked number 2

-

-We figured precision could be ranked lower since it can be sacrificed to an extent without compromising the primary goal of nutmeat integrity.

-

-Structural integrity and repeatability this is essential for the long-term functionality and usability of the design, ensuring it can reliably crack multiple nuts.

-

-Cost seemed less crucial than the other factors, as investing in quality and functionality outweighed immediate cost concerns.

Ideate

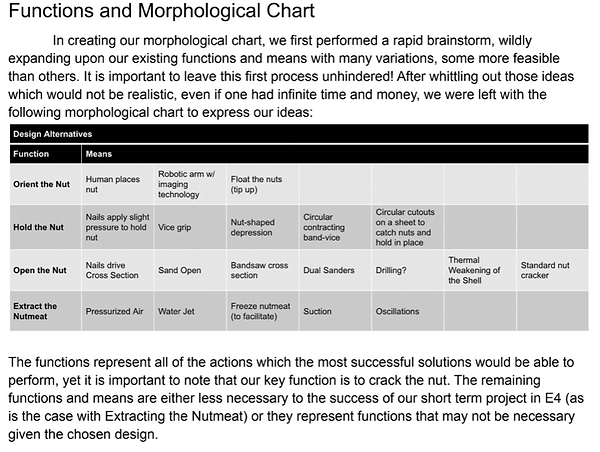

In the spirit charts, we continued on with a morphological chart!

We were ideating many feasible and unfeasible variations. It's important to let our minds run wild when creating ideas.

After going thorugh the idea that weren't realistic, even if one had infinite time and money, we were left with the following morphological chart to express our ideas:

The functions represent the actions that the most successful solutions would be able to perform (our key function is to crack the nut).

The remaining functions and means are either less necessary to the success of our short-term project

or

they represent functions that may not be necessary given the chosen design.

We then came down to 3 feasible designs, to categorize their characteristics we made a design alternatives chart

Let's find the best prototype to use!

We found that the design with the circumference nails will work the best. This is because compared to other designs, this met most of the objectives and constraints required.

Although the circumference nail design isn’t as ingenious as a freezing crusher may be, it’s cost efficient, repeatable with a simpler design, and the materials are easier to attain.

Although the circumference nails are the best design, we plan to test all of these alternatives in order to see if we can implement one design into another for the best outcome and highest yield!

Let's take a quick break for play time!

We decided to break the nut with different types of hammers and mallets to get a physical feel for the strength of the nut.

If we were lucky, like in the picture above it would almost be intact (this took about 79 hits of a hard mallet)

Soft mallets didn't work, only harder hammers worked after about 50 hits.........

Even then the nut would never crack the same way every time

The research about the nut's strength definitely lives up to its name...

I knew we were going to need a very effective prototype..

We then moved on to the prototyping and testing stage....

Our temperature test

Our sanding test proved to be a no-go when it wasn’t giving us equal cuts, making it harder for the 80% yield.

At that point, we came up with this design for our prototype

THIS

We utilized the lathe and mill in our machine shop to create threads in a regular nutcracker, for precision along the nut's "hemispheres"

Womp wom womp.....

With all that in mind,

Let's Iterate!

Had to go back to the drawing board 😉

Where did the drawing board take us, you ask?

Our prototype still utilized functions from the previous one.

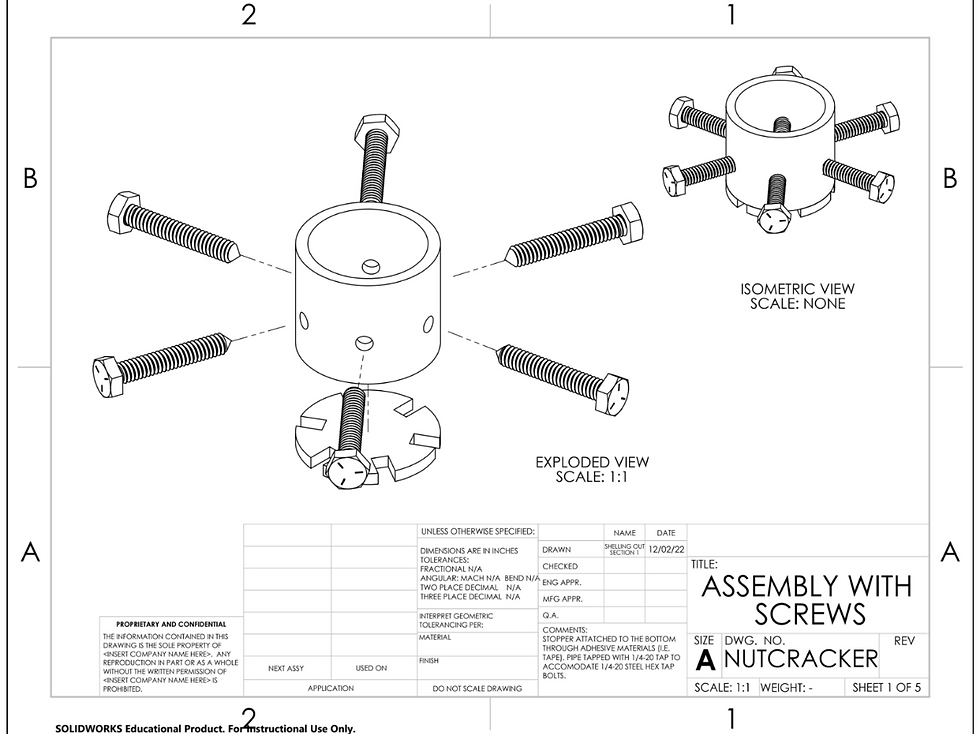

We utilized six screws equal distance apart in a nut holder! (Machined with a pointy tip that would precisely crack the nut along its hemisphere (which we found to be weakest after rapidly cooling the nut with liquid nitrogen)!

Watch our testing process!

From this graph, we found that liquid Nitrogen-dipped nuts required fewer turns to break! ,

Knifes and pointed bolts caused less turns to break!

Heat alone, or paired with liquid nitrogen didn't significantly affect the nutshell compared to liquid nitrogen by itself

Horizontal placement of hemisphere seams required fewer turns while placing the nut vertically required more,

If we had more time,

we'd definitely explore this!

If I had additional time, I would…

Our Bill of Materials!

Which was 500 dollars less than our client's budget max!

My reflection ...

Something new that I learned…

I learned many different ways to rank designs, functions, and pain points. I've always utilized more of a Product Design approach to the define phase, so being able to learn new ways to rank and compare characteristics was extremely impactful!

My biggest challenge was…

Getting past the prototype mental block in the ideation and prototype phase. With not many avenues to take to crack a nut, ideating extensively was hard. On top of that, when our first idea didn't work, almost nothing was coming to mind on how to change our design to crack the nut, we were stuck. Then I thought combining two things rather than one would be the answer. The idea of freezing (expanding) and heating (shrinking) came to mind.

My favorite part was…

Getting to play around with the Liquid Nitrogen! This was something I've always seen on TV but never got to work with myself! The most I've worked with was dry ice, this (dangerous) substance was an unforgettable experience!